China Automated Vision Inspection Solutions

Glass LOGO Inspection Machine

Screen printing errors detection, LOGO QR code identification, LOGO relative position measurement, Ink leakage, ect.

- Architectural Glass

- Automotive Glass

- Display Glass

- Home Appliance Glass

Overview

The glass online inspection system can detect defects in real-time during production and provide product quality information. It records quality data to optimize production processes. The system performs non-contact edge defect detection, surface flaw inspection, and dimensional measurement for products of varying widths and machine speeds.

Using a image sensor, the vision system scans targets in real-time to form images. Specialized image processing and analysis software based on an industrial control computer automatically detects surface defects, measures dimensions, and logs defect data into a categorized database. The system features a user-friendly Windows-based graphical interface.

Installed on the conveyor line after the LOGO printing process, it supports communication via I/O interfaces or industrial Ethernet protocols (Siemens, Mitsubishi PLCs, ect), meeting production line integration requirement.

Highlights

-- Recipe Management

The software allows customized parameter settings for each product type, saved as a “recipe.” During production, simply selecting the recipe automatically loads the corresponding parameters.

-- Classification

Defects are accurately classified using AI-based analysis of captured images, enabling customized criteria for different defect types.

-- Defect Recording (Database Functionality)

Defect characteristics and image data are stored in database files for offline queries, reporting, and printing.

-- Real-Time Interface Display

Instantly shows detected defect images, characteristic data, and trend charts.

Technical Parameter

| Parameter | Value |

|---|---|

| Glass Type | Printed flat glass |

| System Resolution | 0.05 mm |

| Defect Detection Accuracy | 0.1 mm |

| Target Thickness Range | 2mm – 10mm |

| Max. Line Speed Supported | 50 m/min |

| Defect Detection Rate | 98% |

| Inspection Cycle Time | <1 sec (scan to result) |

Detection Capabilities

| Position | Category | Inspection Item | Requirement | Remarks |

|---|---|---|---|---|

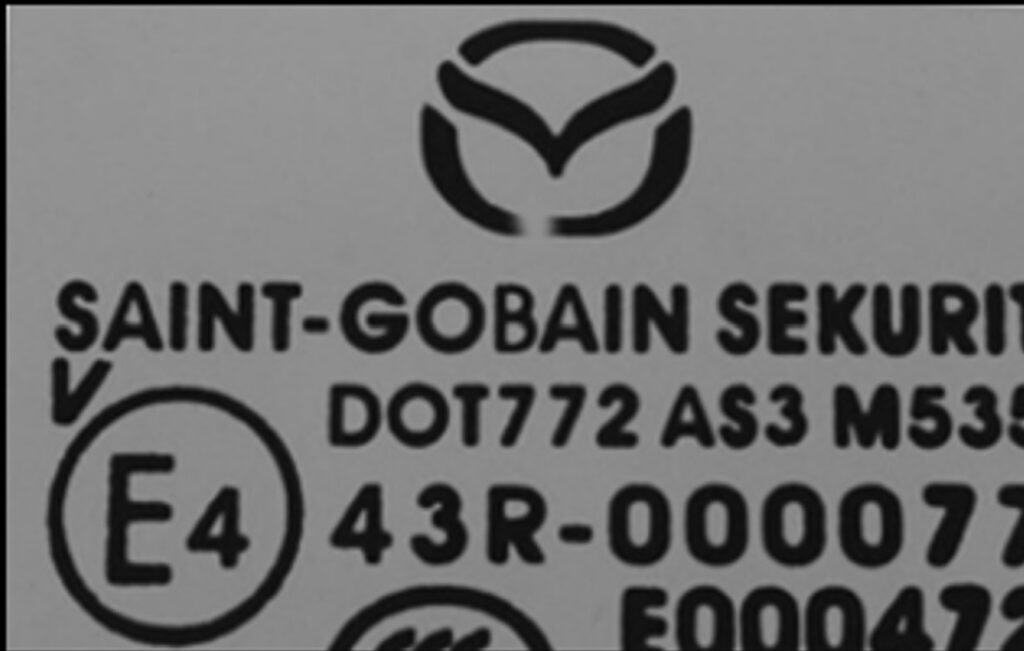

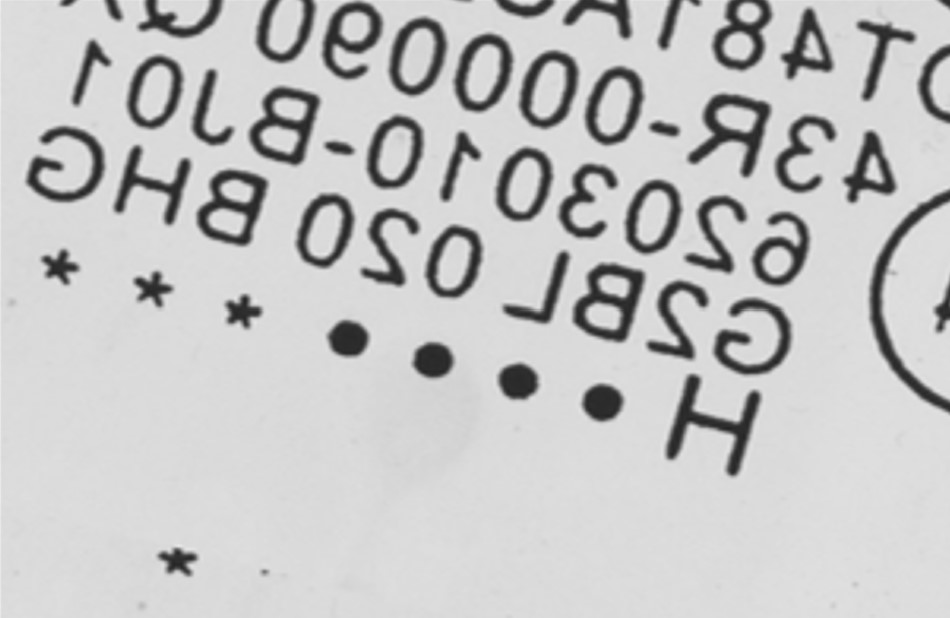

| LOGO | Critical | Character/pattern misprint/omission | 100% detection | Detects missing dot-shaped characters |

| Critical | Character/pattern missing | >2.0% missing per single character | ||

| Critical | Character/pattern blur | Visually apparent | ||

| Critical | LOGO position offset | ±2 mm |

Defects Detected During Projects

-- Character "7" missing, A-hole blockage

-- Ink leakage

-- Automotive emblem line breakage