China Automated Vision Inspection Solutions

Glass Surface Inspection Machine

- Surface Defect Inspection

- Edge Defect Inspection

- Edge Grinding Inspection

- Hole Defect Inspection

- Side Edge Inspection

- Architectural Glass

- Automotive Glass

- Display Glass

- Home Appliance Glass

Overview

The glass online inspection system can detect defects in real-time during production and provide product quality information. It records quality data to optimize production processes. The system performs non-contact edge defect detection, surface flaw inspection, and dimensional measurement for products of varying widths and machine speeds.

Using a linear image sensor, the vision system scans targets in real-time to form images. Specialized image processing and analysis software based on an industrial control computer automatically detects surface defects, measures dimensions, and logs defect data into a categorized database. The system features a user-friendly Windows-based graphical interface.

Highlights

-- Recipe Management

The software allows customized parameter settings for each product type, saved as a “recipe.” During production, simply selecting the recipe automatically loads the corresponding parameters.

-- Classification

Defects are accurately classified using AI-based analysis of captured images, enabling customized criteria for different defect types.

-- Defect Recording (Database Functionality)

Defect characteristics and image data are stored in database files for offline queries, reporting, and printing.

-- Real-Time Interface Display

Instantly shows detected defect images, characteristic data, and trend charts.

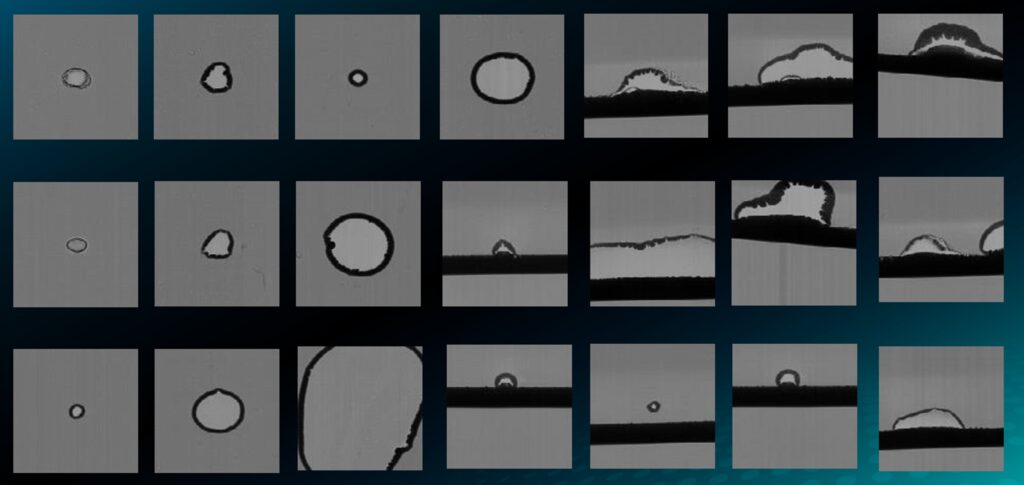

Defects Classification (Top/Bottom Surfaces & Internal)

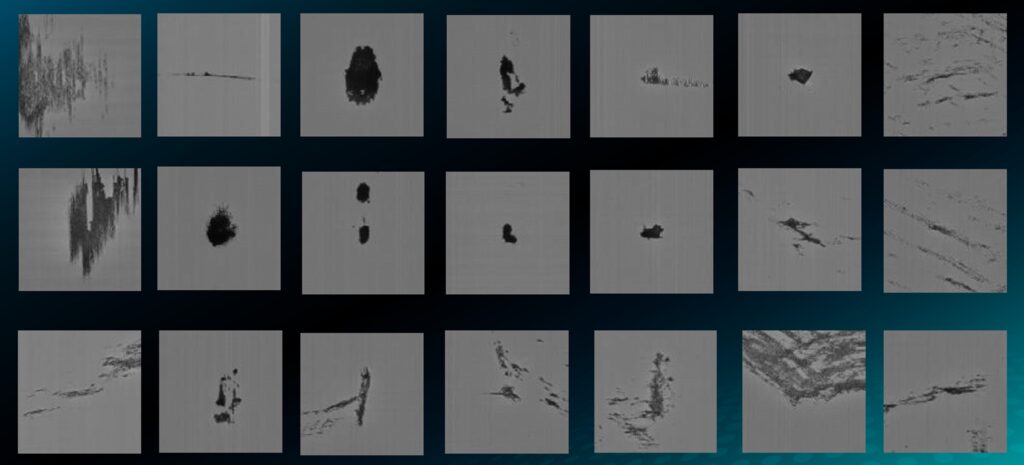

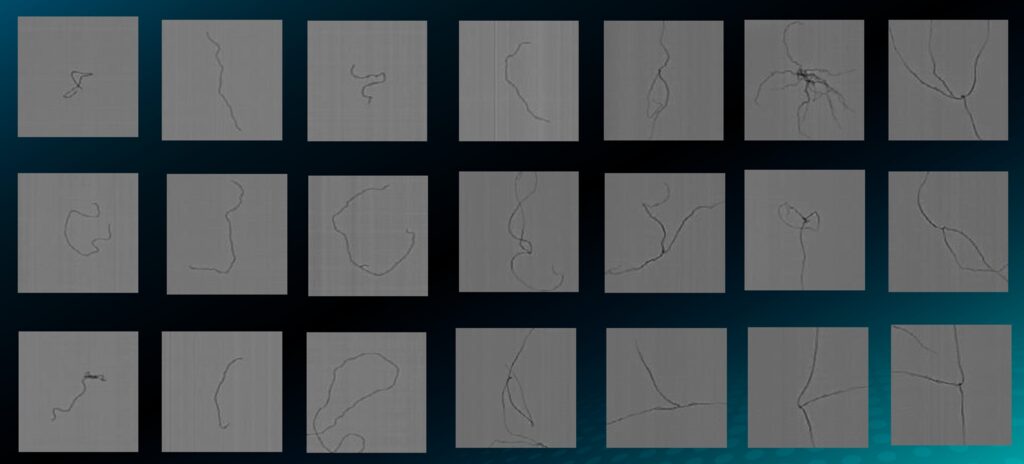

-- Surface Defects

Bubbles, stone inclusions, tin spots, dirt, scratches, glass fragments, water stains, color stains.

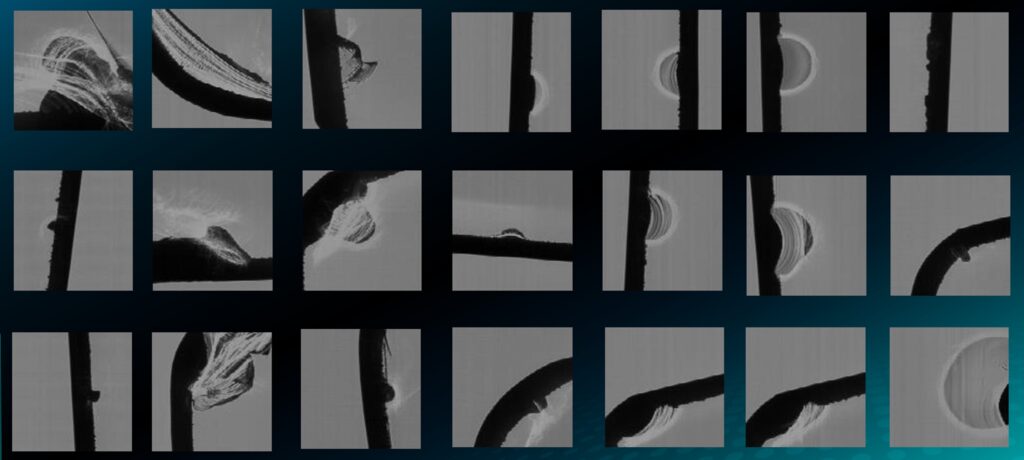

-- Edge Defects

Chipped edges, missing corners, cracks.

-- Grinding Defects

Unground areas, insufficient grinding, over-grinding.

-- Hole Defects

Hole diameter deviations, missing holes, hole edge cracks, chipped hole edges.

-- Side Defects

Burnt edges, glossy edges, fragmented edges.

Machine Performance Specification

| Parameter | Value |

|---|---|

| Glass Form | Flat Glass |

| Physical Resolution | 0.021 mm |

| Defect Detection Accuracy | 0.04 mm |

| Dimensional Accuracy (Longitudinal accuracy affected by conveyor) | 0.1 mm |

| Detectable Target Width | Refer to model-specific conveyor width |

| Detectable Thickness | 0.5 mm – 40 mm |

| Line Speed | 5 m/min – 50 m/min |

| Defect Detection Rate | 99% |

| False Detection Rate (Affected by glass cleanliness) | 1% |

| Minimum Grinding Width | 0.3 mm |

| Minimum Hole Diameter | 4 mm |

| Minimum Edge-to-Hole Distance | 4 mm |

| Maximum Operating Temperature | 45°C |

| Minimum Roll Gap for Inspection | 70 mm |

Defects Detected During Projects

-- Scratches

-- Bubbles

-- Chipped Edges

-- Dirt

-- Fibers

-- Glass Fragments and Insect Marks

-- Water Stains