China Automated Vision Inspection Solutions

Nonwoven Fabric Inspection Machine

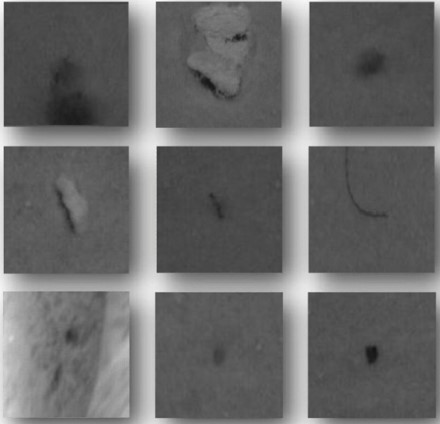

Detectable Defect Types:

Holes, unmelted particles, resin spots, insect inclusions, etc. (as illustrated)

Inspection Targets:

Nonwoven in production processes including:

Spunbond, spunlace, thermal-bonded, chemical-bonded, and air-through nonwoven materials

Overview

The glass online inspection system can detect defects in real-time during production and provide product quality information. It records quality data to optimize production processes. The system performs non-contact edge defect detection, surface flaw inspection, and dimensional measurement for products of varying widths and machine speeds.

RVT-Nonwoven Vision utilizes high-resolution line-scan cameras to capture nonwoven fabric images. Specialized image processing and analysis software based on an industrial control computer automatically detects surface defects, measures dimensions, and logs defect data into a categorized database. The system features a user-friendly Windows-based graphical interface.

Highlights

-- Recipe Management

The software allows customized parameter settings for each product type, saved as a “recipe.” During production, simply selecting the recipe automatically loads the corresponding parameters.

-- Classification

Defects are accurately classified using AI-based analysis of captured images, enabling customized criteria for different defect types.

-- Defect Recording (Database Functionality)

Defect characteristics and image data are stored in database files for offline queries, reporting, and printing.

-- Real-Time Interface Display

Instantly shows detected defect images, characteristic data, and trend charts.

Machine Performance Specification

Core Components:

High-performance industrial computer

Proprietary image processing software (fully independent IP)

High-res line-scan cameras (2K-16K resolution)

Long-life LED illumination

Dedicated tooling & fixturesPerformance:

Scalable camera configuration for resolution adjustment

Max. line speed: 600 m/minCapabilities:

Pre/post-production surface defect detection

Automatic defect coordinate logging (machine & cross directions)

AI-based defect classification

Automatic defect image archiving

Auto-generated roll quality reports & defect distribution maps

Defects Detected During Projects